What Are Custom Patches and Why Do They Matter in Global Merchandising?

Custom patches are branded fabric embellishments designed to represent companies, organisations, or products across international markets. These versatile marketing tools transform ordinary garments and accessories into powerful brand ambassadors that travel worldwide with their wearers.

The choice of Custom patches materials directly impacts both brand perception and product longevity. Premium materials like leather or PVC convey quality and durability, whilst embroidered options offer cost-effective solutions for large-scale campaigns. Each material tells a different brand story—from rugged outdoor aesthetics to refined corporate imagery.

Material selection becomes critical when patches face diverse global environments. A patch designed for tropical climates requires different durability standards than one intended for urban settings or harsh outdoor conditions.

This guide examines the most effective materials for custom patches in global merchandising, helping brands make informed decisions that balance:

- Aesthetic appeal with functional requirements

- Budget considerations with quality expectations

- Environmental durability with design complexity

Understanding these material choices ensures your branded patches maintain their impact across every market they enter.

What Are the Most Common Materials Used for Custom Patches?

There are six main materials used for custom patches, each with its own unique qualities that cater to specific merchandising needs.

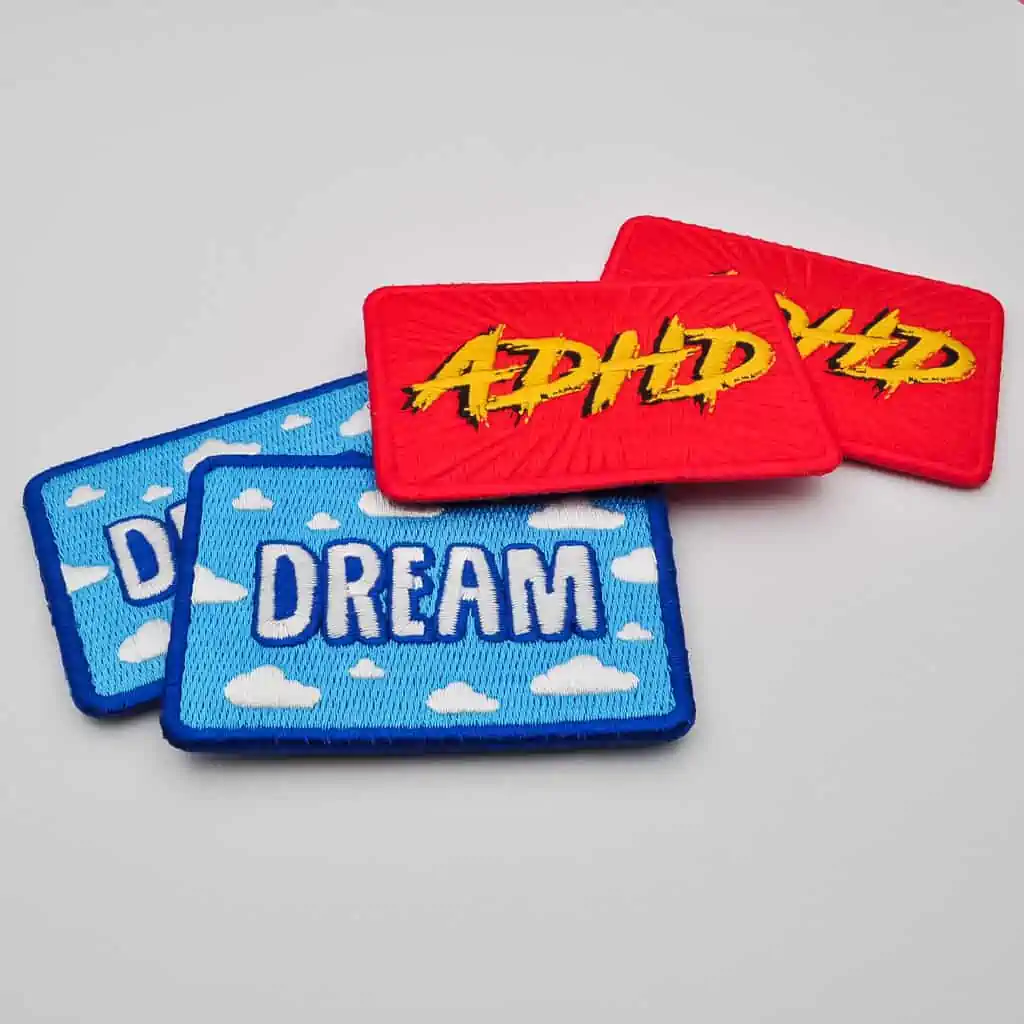

1. Embroidered Patches

Embroidered patches use thread stitched onto a twill fabric base, creating a raised, textured appearance that works exceptionally well for bold logos and simple designs on caps, uniforms, and denim jackets.

2. Woven Patches

Woven patches take a different approach by weaving threads together rather than layering them, resulting in a flat, smooth finish ideal for intricate details and fine text. This precision makes them perfect for complex brand logos requiring sharp definition.

3. PVC Patches

PVC patches stand out for their exceptional durability and water resistance, making them the go-to choice for outdoor gear and activewear where exposure to elements is a concern. Their rubber-like texture provides a modern, professional appearance.

4. Leather Patches

Leather patches deliver premium aesthetics with their naturally rugged texture and inherent water resistance. These patches elevate products like trucker hats and high-end apparel with their sophisticated appearance.

5. Chenille Patches

Chenille offers a distinctive fuzzy texture traditionally associated with letterman jackets and varsity wear, providing a classic collegiate aesthetic that appeals to specific market segments.

6. Felt Patches

Felt patches provide the softest texture with vintage charm, though they require more careful handling and are best suited for indoor applications or gentle-use items where their delicate nature won’t compromise functionality.

How Do Embroidered and Woven Patches Differ in Design and Use?

Embroidered patches create their distinctive raised texture through thread stitched directly onto a twill fabric base. This construction method produces bold, dimensional designs that catch light naturally, making logos and text appear prominent from a distance. The cost-effectiveness of embroidered patches makes them ideal for large merchandising runs, particularly when budgets require maximum impact per unit.

Woven patches achieve their smooth, flat finish by weaving threads together during manufacturing rather than stitching on top. This technique allows for intricate details, fine lines, and small text that would be impossible with embroidery. The patch texture remains consistently smooth, creating a professional appearance suitable for premium merchandise.

Design Complexity Considerations

When evaluating design requirements, it is important to consider the differences between embroidered vs woven patches:

- Bold logos and simple graphics: Embroidered patches excel with their textured appeal

- Detailed artwork and small text: Woven patches deliver crisp, clean lines

- Colour gradients: Woven patches handle subtle colour transitions better

Optimal Applications

Embroidered patches are well-suited for denim jackets, backpacks, and baseball caps where durability and visual impact matter most. On the other hand, woven patches work exceptionally well on dress shirts, polo shirts, and premium headwear where refined appearance takes priority. Sports teams often choose embroidered patches for fan merchandise, whilst corporate brands frequently select woven patches for executive apparel and trade show giveaways.

Why Are PVC and Leather Patches Preferred for Outdoor or Premium Apparel?

Durability of PVC Patches

PVC patches durability makes them the go-to choice for merchandise exposed to harsh conditions. These synthetic patches resist water, UV rays, and extreme temperatures whilst maintaining their vibrant colours and structural integrity. Their flexibility prevents cracking during repeated bending, making them perfect for active wear and outdoor gear.

The waterproof nature of PVC patches eliminates concerns about moisture damage, mould, or colour bleeding. This reliability extends their lifespan significantly compared to fabric-based alternatives, reducing replacement costs for brands operating in challenging environments.

Water Resistance of Leather Patches

Leather patches water resistance combines functionality with premium aesthetics. Genuine leather develops a distinctive patina over time, creating an authentic vintage appeal that resonates with consumers seeking quality craftsmanship. The material’s natural durability withstands daily wear whilst projecting sophistication.

Leather patches require minimal maintenance – spot cleaning with a damp cloth suffices for most situations. Avoid soaking or machine washing to preserve the material’s natural oils and prevent cracking.

Benefits for Outdoor Gear

Outdoor gear patches benefit immensely from these materials:

- Hiking jackets – PVC patches withstand rain and abrasion

- Trucker hats – Leather patches complement rugged styling

- Work uniforms – Both materials resist industrial environments

- Sports equipment bags – PVC handles moisture and rough handling

These materials elevate brand perception by demonstrating commitment to quality and durability in demanding applications.

4. In What Situations Are Chenille and Felt Patches Best Utilized?

Chenille patches usage centres around their distinctive raised texture and premium appearance, making them the gold standard for academic and athletic letterman jackets. The looped yarn construction creates a plush, three-dimensional surface that catches light beautifully, giving these patches an unmistakable luxury feel that commands attention. Click here to learn about how can Acrylic Pins help businesses reach younger global audiences?.

Traditional varsity applications showcase chenille’s strengths perfectly:

- School letter patches on letterman jackets

- Team mascot designs for sports merchandise

- Achievement badges for academic honours

- Premium branded apparel requiring tactile appeal

On the other hand, felt patches vintage look delivers authentic retro aesthetics with remarkable softness, perfect for heritage brands and nostalgic merchandise campaigns. The natural fibres create warm, muted colours that evoke classic Americana and timeless craftsmanship. These felt patches are also known for their versatility in various applications.

Patch Care Requirements Demand Special Attention

Both materials require gentle handling to maintain their appearance:

- Chenille: Brush gently to restore texture; avoid machine washing when possible

- Felt: Hand wash in cold water; air dry flat to prevent shrinkage

- Storage: Keep in dry environments away from moisture and direct sunlight

Environmental limitations restrict their use to indoor or mild weather applications. Chenille’s loops can snag on rough surfaces, whilst felt absorbs moisture readily, making both unsuitable for heavy-duty outdoor gear or frequent washing cycles.

5. How Do Backing Options Influence Patch Usability in Global Merchandising?

Iron-on backing provides the quickest application method, using heat-activated adhesive that bonds patches directly to compatible fabrics like cotton, denim, and polyester. This backing excels for temporary applications or items requiring frequent washing, though it may not adhere well to leather or heavily textured materials.

Sew-on backing delivers maximum durability and versatility across all fabric types. Professional merchandisers favour this method for:

- Heavy-duty uniforms and workwear

- Leather accessories and premium apparel

- Items subjected to frequent washing or harsh conditions

- Permanent branding applications

Velcro backing enables complete removability, making it ideal for tactical gear, sports equipment, and interchangeable branding systems. The hook-and-loop mechanism allows users to swap patches based on team affiliations, seasonal campaigns, or personal preferences.

Each backing type affects fabric compatibility differently. Iron-on works best with smooth, synthetic blends, whilst sew-on accommodates any material thickness. Velcro requires compatible loop fabric or additional backing material. The choice between permanent attachment and removability directly impacts the patch’s intended lifespan and user experience in global markets.

6. What Factors Should Be Considered When Choosing Patch Materials for Different Merchandise?

Successful patch material selection criteria depend on matching the right material to specific merchandise requirements and usage conditions. The garment type dictates material compatibility – leather patches excel on trucker hats and premium caps, whilst embroidered patches perform better on fabric jackets and uniforms.

Garment compatibility extends beyond aesthetics to practical considerations:

- Hats and caps: Woven or leather patches provide clean lines and professional appearance

- Jackets and outerwear: PVC and embroidered patches withstand frequent washing and wear, making them suitable for items that require cleaning procedures

- Backpacks and bags: Durable materials like PVC resist abrasion from daily use

- Uniforms: Embroidered patches offer cost-effectiveness for bulk orders

Environmental exposure assessment ensures patch longevity across different markets. Outdoor merchandise requires water-resistant PVC patches, whilst indoor corporate apparel can utilise softer felt or chenille materials. Climate considerations matter – humid environments favour moisture-resistant options, whilst dry conditions allow broader material choices.

It’s essential to conduct a thorough environmental exposure assessment to determine the best materials for specific conditions.

Budget constraints influence material selection, with embroidered patches offering cost-effectiveness for large runs and woven patches justifying higher costs through superior detail reproduction. Order quantities affect pricing structures, making certain materials more viable for specific merchandising campaigns.

How Does Choosing the Right Patch Material Enhance Brand Identity Globally?

High-quality patch materials serve as silent ambassadors for your brand, creating consistent impressions across international markets. The material you select directly influences how customers perceive your brand’s commitment to quality and attention to detail.

Premium materials like woven patches communicate sophistication and precision, making them ideal for luxury brands targeting discerning global audiences. PVC patches project durability and reliability, perfect for outdoor or technical brands establishing credibility in rugged market segments.

Brand identity enhancement occurs when patch materials align with your brand’s core values:

- Embroidered patches convey traditional craftsmanship and heritage

- Leather patches suggest premium quality and exclusivity

- Chenille patches evoke nostalgia and authenticity

Consistent material choices across different merchandise categories create cohesive brand recognition worldwide. When customers encounter your patches on various products—from caps in Tokyo to jackets in London—the familiar texture and appearance reinforce brand memory.

What Materials Work Best for Custom Patches in Global Merchandising? The answer lies in selecting materials that not only withstand diverse climates and usage patterns but also consistently communicate your brand’s unique identity across every touchpoint.

FAQs on Custom Patches in Global Merchandising

Custom patches are branded fabric embellishments used to represent companies, products, or organizations. They act as portable brand ambassadors, reinforcing brand identity and creating consistent impressions across global markets.

The six main materials are: embroidered, woven, PVC, leather, chenille, and felt. Each material offers unique qualities that cater to different merchandising needs, durability requirements, and brand aesthetics.

Embroidered patches feature raised threads, ideal for bold logos and large-scale merchandising.

Woven patches are flat and smooth, perfect for intricate designs, small text, and fine details requiring precision.

PVC patches are highly durable, water-resistant, and flexible, suitable for activewear and harsh environments. Leather patches convey premium quality and sophistication, ideal for high-end apparel or accessories.

Chenille patches are best for varsity jackets, school letter patches, and premium tactile branding.

Felt patches provide a vintage aesthetic for indoor merchandise or gentle-use items, ideal for retro or heritage-inspired products.

Iron-on: Quick application for smooth fabrics and temporary use.

Sew-on: Permanent and durable, suitable for all fabric types.

Velcro: Removable, ideal for tactical gear or interchangeable branding systems.